WOOD GAS

Hochreiter’s wood gas CHP units

We plan your individual wood gas plant together with you and our network of competent partners.

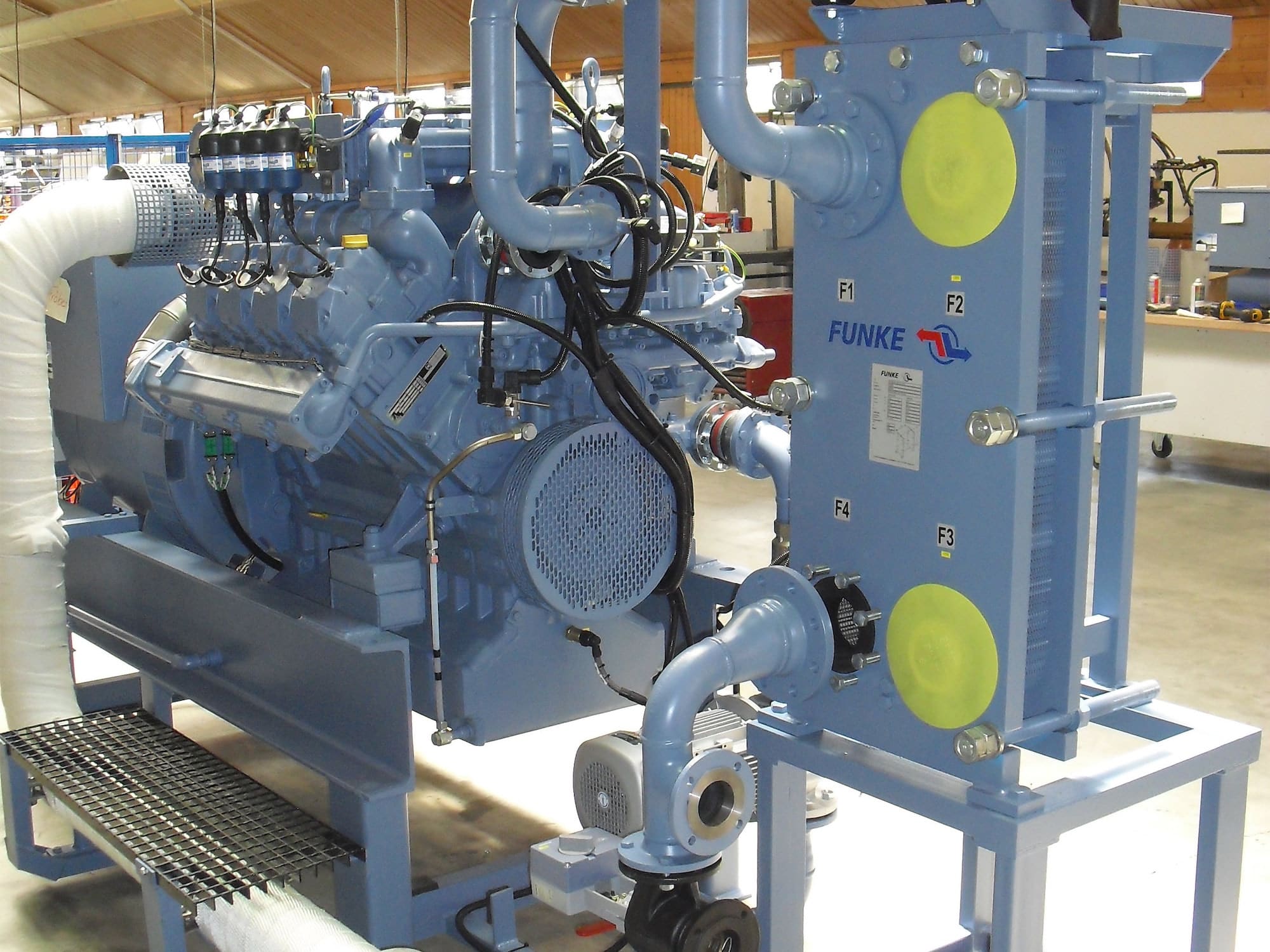

HODEUTZ V6 150 kW

Technical data:

- Engine: Deutz V6 turbo

- Cubic capacity: 11.9 liters

- Power electr.: 150kW at 1500 rpm

- Power therm.: 230kW

Facts:

- Robust and compact V-motor

- Proven four-valve technology with prechamber spark plugs

- Large oil volume with external oil cooler

- Best possible heat extraction through large-dimension heat exchangers

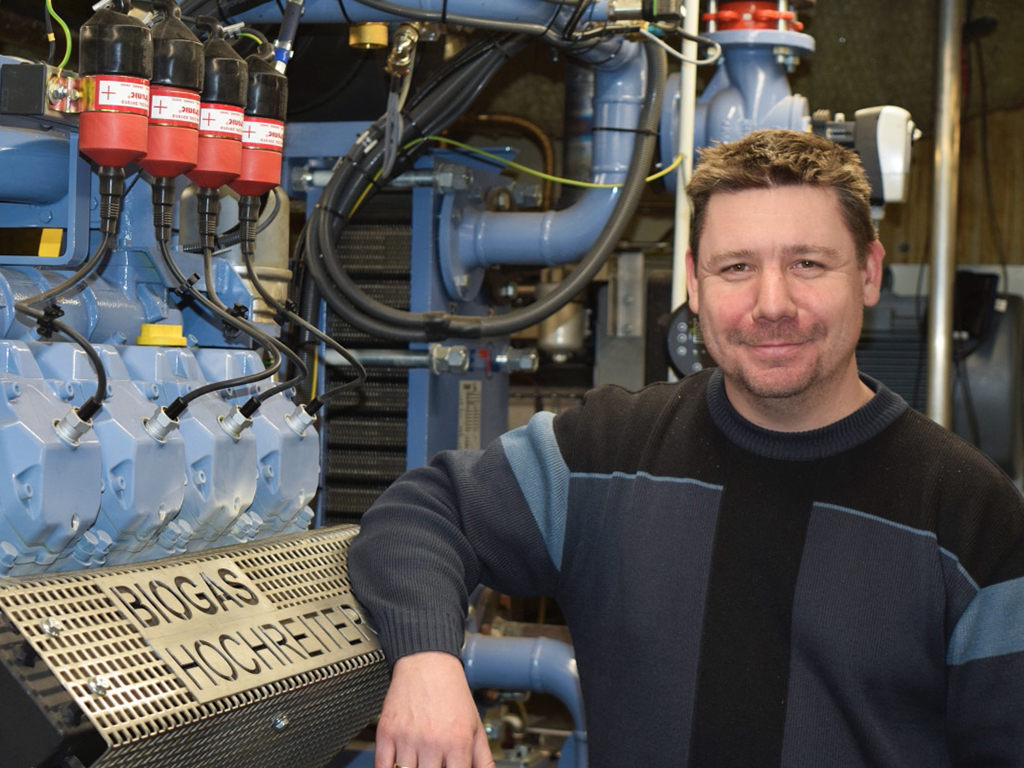

Blasius Gerg

“We rely on regional products for our energy production. Sustainability and suppliers close to home are top priorities for us, which is why we chose Biogas Hochreiter from Schnaitsee.”

Glonntal Strom is a small electricity grid operator with 100% regional green electricity.

We replaced two small CHP’s, each with 50kW, with a powerful Hochreiter wood gas CHP, type HODEUTZ V6, in 2021. The 150kW genset from Hochreiter takes over a significant part of the basic electrical supply here, combined with hydropower and photovoltaics. We work together with the Stadtwerke Rosenheim, to supply 100% green electricity to the village of Piusheim and the surrounding villages within a radius of 50km. The generated continuous thermal power of 200kW is fed into the regional district heating network.

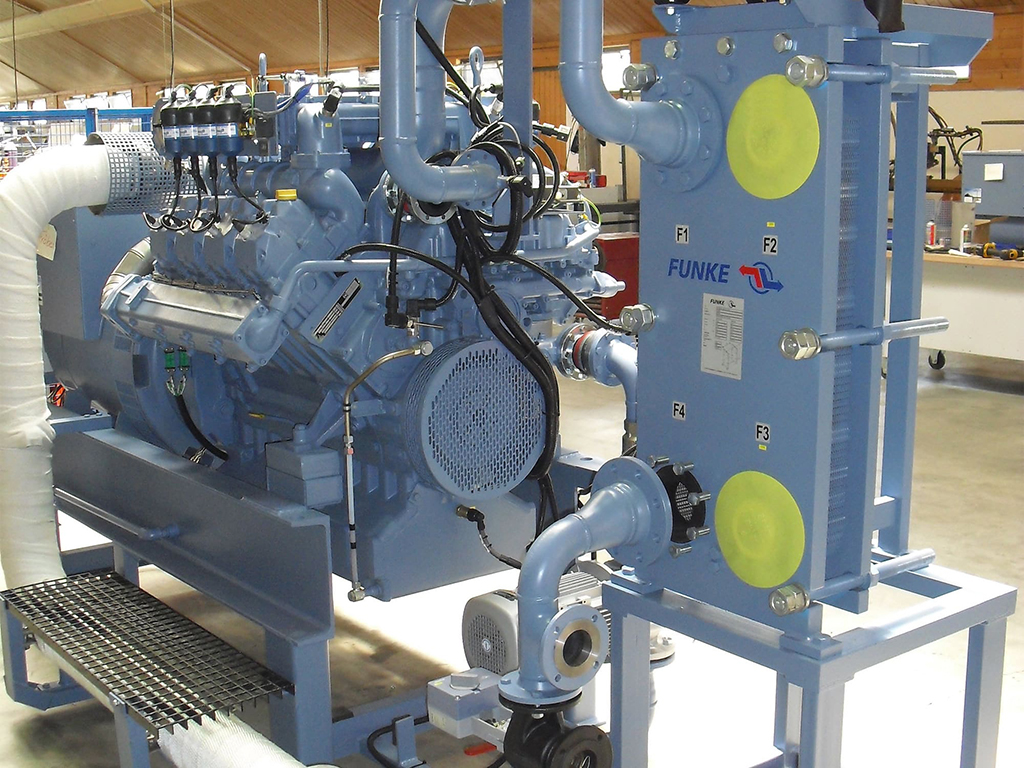

HODEUTZ V8 210 kW

Technical data:

- Engine: Deutz V8 turbo

- Cubic capacity: 15.9 liters

- Power electr.: 210kW at 1500 rpm

- Power therm.: 280kW

Facts:

- Quiet V8 engine

- Large volume cubic capacity

- Longer oil level times due to additional oil cooler

- Highly efficient charge air cooling, with additional thermal power

Sepp Weber

“As a civil engineer, I have given a lot of thought to the construction and operation of the wood gas plant and have constantly developed it over the years. I started to work with the simplest means and gained my experience. I have raised my plant to a higher level, with the decision to install a highly efficient Hochreiter CHP unit. In my main job as a civil engineer, I enjoy meanwhile advising new & existing Hochreiter customers who have decided to build a new wood gas plant or increase its efficiency.”

Sepp Weber, owner of EVU Lohen started with the first wood-fired power plant in 2012 and then continuously expanded the plant up to 110kWel.

The three small ́s CHP units were replaced by an efficient HODEUTZ V8 with 210kW electrical output in 2021. The electrical energy produced is profitably remunerated by Stadtwerke Rosenheim in direct marketing. Additional revenue is also generated through the sale of heat.

The thermal output of 280kW is fed into the local district heating network, thereby supplying 10 households and the company’s own theater stadium with sustainable CO2-neutral heat. Sepp also operates a contract drying for hay, straw, etc. with the surplus heat. The regional wood chips used are also dried with the specially produced heat on site.

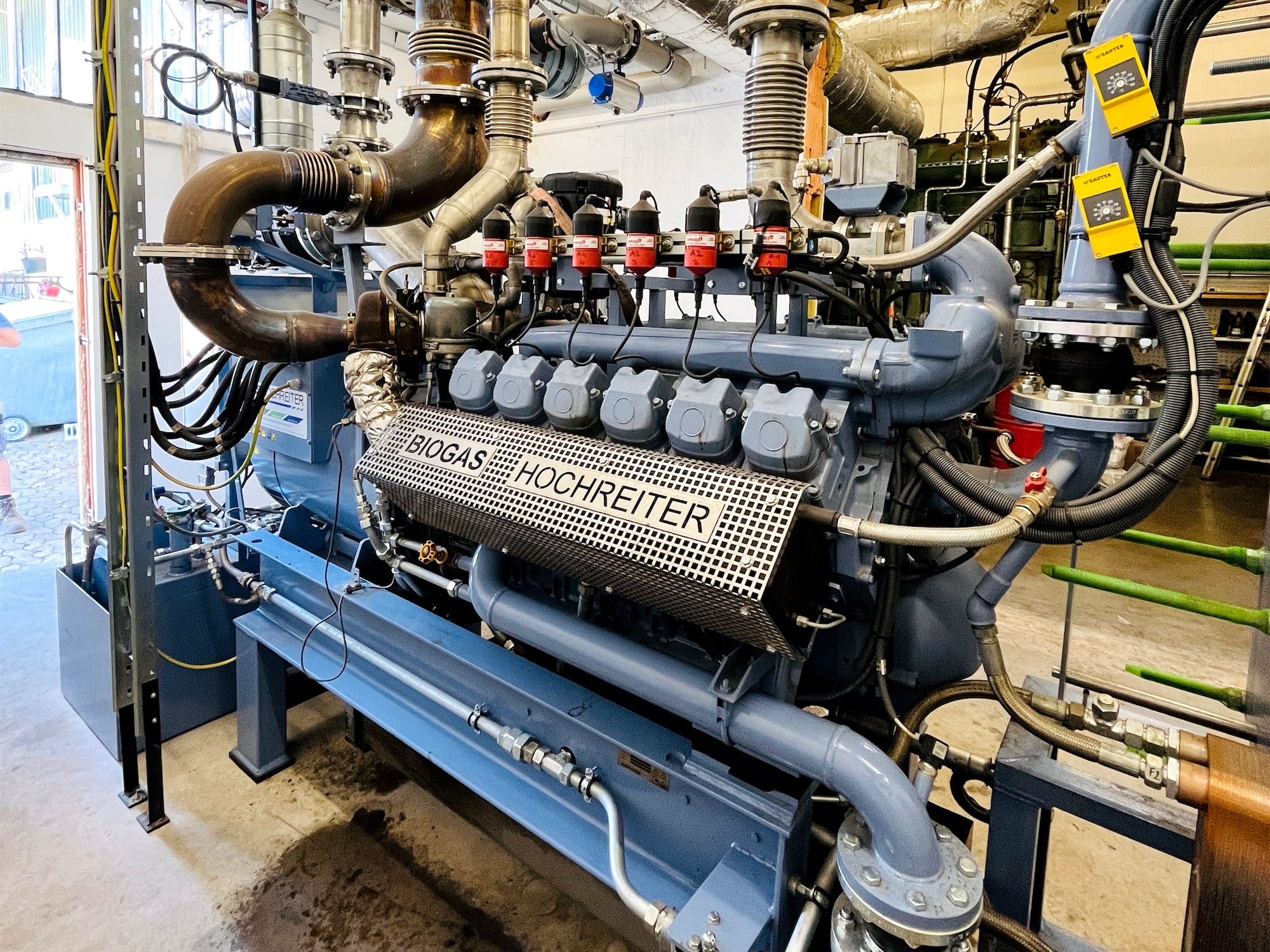

HOMAN H130LE 285 kW

Technical data:

- Engine: Hochreiter H130 biturbo

- Cubic capacity: 22.62 liters

- Electr. power: 285kW at 1500 rpm

- Power therm.: 420kW

Facts:

- 12 cylinder V-engine, biturbo

- Large volume cubic capacity

- Optimized flow paths

- Electric prelubrication pump

- Motor temperature maintenance

- Longer oil intervals due to increased oil volume of 360 liters

- Water jacketed exhaust manifold

Lechner/Schlipf

“From the beginning, we wanted to run our plant at maximum capacity and utilization. Our experience has shown that continuous modernization of our wood gas plant will enable us to continue operating economically in the future. An important component in our development is the Hochreiter wood gas CHP Type H130LE. We can now benefit from the 300 KWel, with optimal wood chip and wood gas quality, performance in direct marketing and see ourselves well equipped for the future.”

The Lechner wood chip company in Ellenberg went into operation in 2011 with a 6-cylinder marine diesel engine with a displacement of 23.1 liters and its wood gas system. The plant was modernized and equipped with new wood gasifiers in 2020.

In order to further increase profitability and efficiency, Mr. Lechner decided in 2022 to replace the aging marine diesel with a new, state-of-the-art wood gas CHP, type H130 from Hochreiter. The 12-cylinder CHP with charge air cooling and biturbo generates up to 300 kWel with the appropriate wood gas supply power and approx. 420 kW continuous thermal power. The waste heat is mainly utilized for drying bulk materials such as wood chips and bark mulch on site.

The majority of the electrical power generated is profitably marketed on the electricity exchange or remunerated via the EEG, in cooperation with a direct marketer. The plant thus benefits from the highly profitable electricity market prices and was able to replace the costly ignition oil component in a completely CO2-neutral manner. Mr. Lechner has taken a big step towards an economically secure and sustainable future by modernizing his plant.

CHP Container Solutions

Hochreiter supplies CHP ́s in system concrete elements with sound absorption, as a turnkey solution, As an alternative to a CHP building,

The fully installed CHP ́s are ready for operation and only need to be connected to the gas line and transformer.

The advantages of the containers are the solid construction, the almost soundproof construction and the possibility to customize them to your needs.